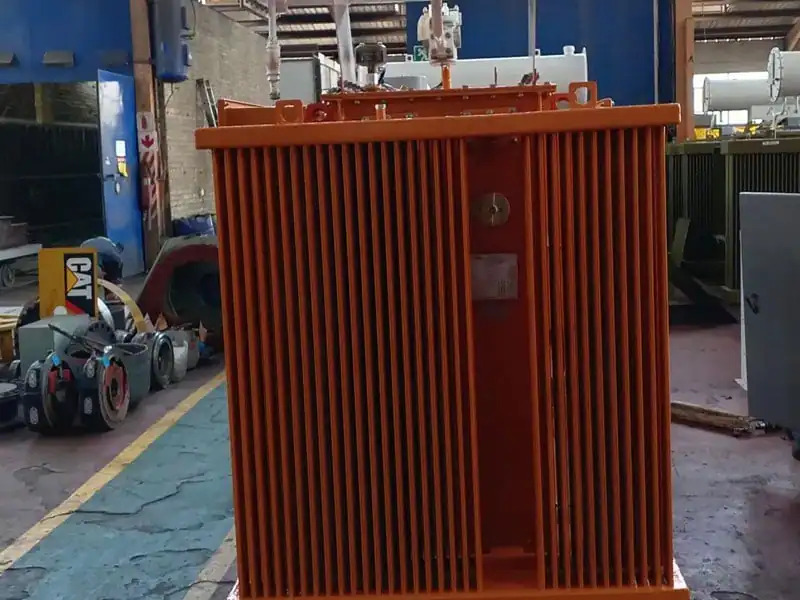

Distribution Transformers and MV Miniature Substation Repairs

ArmCoil takes pride in delivering exceptional transformers and MV miniature substation repairs services at our state-of-the-art facility in Roodepoort, Johannesburg, South Africa.

ArmCoil strictly complies with ISO management accreditations, IEC & SANS780 specifications for transformers and MV miniature-substations, offering repair services for various equipment types, including ONAN, ONAF, KNAF and Dry Types.

Spanning over 8500 m2 under roof, our work area is equipped with a maximum 50-tonne overhead remote crane, among other cutting-edge lifting equipment. The facility and its contents are comprehensively insured, with 24-hour security ensuring the utmost protection.

ArmCoil’s commitment to excellence is evident in our meticulous approach to distribution transformer and mini-substation repairs, offering comprehensive services with a focus on quality, reliability, and longevity.

Capabilities of our Distribution Transformer & MV Miniature-Substation Repair Services Include:

Full Condition Assessments

Comprehensive evaluations with detailed repair recommendations/scope of works.

Failure Reports.

Root cause of failure reports.

Full Rewinding

Expert rewinding services on all types of distribution transformers up to 132 000V (132kV).

Localised Coil & Supply Lead Repair

Targeted repair services where feasible.

Time & Temperature Controlled Curing Oven Facilities

Ensuring precision in the repair process.

All ovens are calibrated.

Complete Test Bay Facility

Equipped with Calibrated Testing Equipment For:

• No Load Testing or Routine Testing.

• Load Testing.

• Temperature Stabilising Testing.

• Efficiency Comparison Testing.

• Oil Sampling and Testing in Accordance with SANS555.

• Full Voltage Testing.

• Ratio Testing.

• SFRA Testing.

• LV, MV Equipment Testing, Including Lighting Compartments.

• Special tests are available on request.

Transformer & MV Mini-Substation Core Repairs

Expert services for core repairs and replacement.

RMU Refurbishment or Replacement

Ensuring optimal performance of Ring Main Units.

Cooling Upgrades & Redesign

Enhancements to cooling systems for improved efficiency.

Heat exchanger designs available.

Sandblasting & Respray Facility

Restoring aesthetics with meticulous sandblasting and respraying.

Mechanical Repairs & Upgrade

Upgrading mechanical components for enhanced performance.

Radiator Replacement & Repairs

Expert services for radiator maintenance and replacement.

Conservator Replacement & Repairs

Ensuring the integrity of conservators.

Main Tank Replacement & Repairs

Comprehensive services for main tank maintenance and replacement.

LV & HV Box Replacement & Repairs

Expertise in low and high-voltage box maintenance.

Auxiliary Parts Replacement & Servicing

Full-spectrum services for auxiliary parts.

Transformer Pressure Testing for Leaks

Rigorous testing to identify and address leaks.

Mechanical Design & Manufacturing

Tailored solutions for the design and manufacturing of distribution transformers for upgrade purposes.

Factory Acceptance Testing Services (FAT)

Rigorous testing to ensure compliance before deployment.

OEM Assembly & Testing

Original Equipment Manufacturer assembly and testing for distribution transformers.